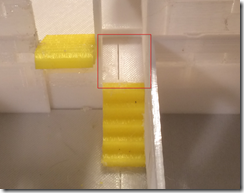

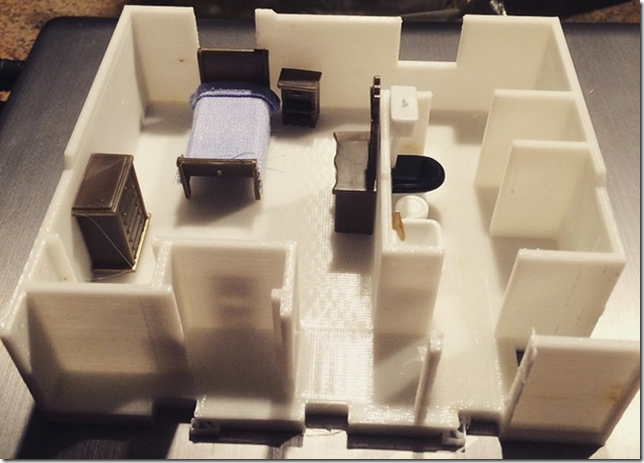

I have 3.5 floors printed! And they go together! With Stairs!

|

|

|

|

There are some problems:

I have ordered a 2kg (5.5 lb) spool of white (“Studio Line White” from JustPLA.com); With it I’m going to start over. This time:

- Correct the basement height

- Put the stairs in from the start so they get “cut” correctly.

- I want to reflect where the ground level is better.

~~~~~~~

For this blog post, I snapped this tag:

https://github.com/sunnywiz/housejscad/tree/Post4

When I get time, I plan on making a how-to video – for my own benefit, since a year from now I won’t remember the details:

- How to create the blueprint

- How to size the blueprint to create the text overlap

- How to use the code to generate the STL’s

- How to use the Join libraries to make the pieces possibly fit each other

- How to use the Cut libraries to make things printable on my print bed and Plate them

- How to use the Microsoft / NetFabb Cloud service to fix the model

- How to use Blender to section the shells off into separate prints

- How I glued things together (as best as I have found so far)