We’re back in business!

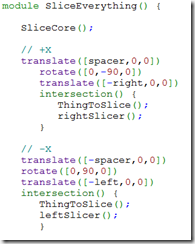

The last time I had tried to print something, I noticed a bunch of smoke coming out of “C” in the diagram below. And things were dripping too freely. I had the thermister at position “A” below, just how its supposed to be.

Thanks to acquiring a digital thermometer capable of measuring temperatures up to 200C, I was able to read my own temperatures – and sure enough – Fred in this chart. The real temperature in the barrel was much higher than was being read. Why? This makes no sense!

Thanks to acquiring a digital thermometer capable of measuring temperatures up to 200C, I was able to read my own temperatures – and sure enough – Fred in this chart. The real temperature in the barrel was much higher than was being read. Why? This makes no sense!

Well, luckily I had watched a video on how to put a print head back together, and it turns out that I had not looped some Kapton tape around the nozzle first, I had put the thermister directly on there, and then covered it up with tape. I tried it the other way: One loop around with tape, then the thermister, and then another layer of tape, yielding sample Barney. (I also put the fiberglass insulation (tattered, but still in one piece) on it like they suggested.

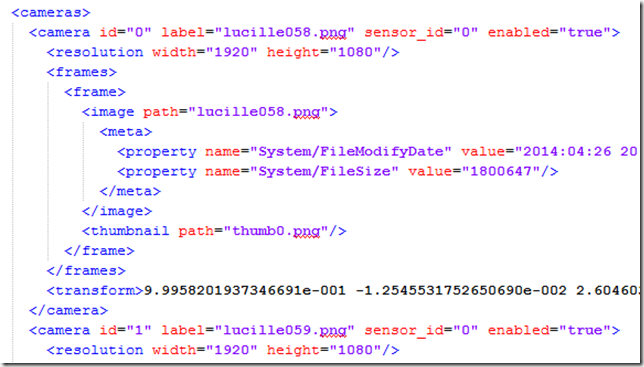

| Sample |

Thermister Location |

Temp (C) |

Reference Thermometer location |

Temp (C) |

| Fred |

A / Direct |

130 |

C |

170 |

| Barney |

A / Kapton |

130 |

C |

125 |

| Scooby |

B |

130 |

C |

125 |

Much better! We’re in business.. almost. While printing, the tape gave way and the thermister fell off.

Why, I wonder? My guess is that by having one loop of kapton tape, and kapton tape is a good heat transfer agent, it gets to sample the average heat from all around the nozzle, all around the thermister, rather than just one side of the thermister. Or something like that. Or maybe there’s just a bad spot on nozzle and I was unlucky.

I tried taping it back on 2 more times. No luck. I seem to have done something to the print head, the wires are shorter now, and after much cursing and screaming, I gave up.

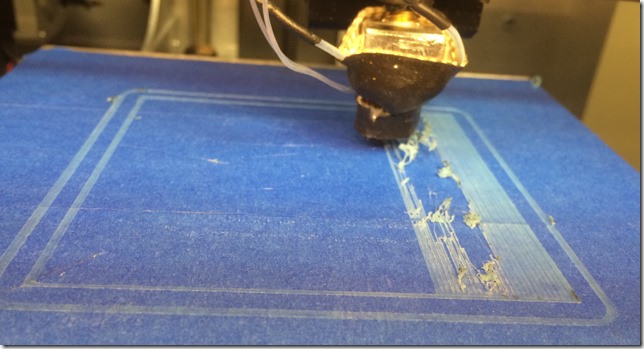

Instead, I put the thermister in at location “B” – inside the fiberglass insulation, which held it snugly in place – and yielded sample Scooby. We still seemed to be in business. And here it is, printing:

The URL to the above camera is https://www.dropcam.com/p/sunnywiz, although there is no guarantee that it will be pointed at a geeky subject at the time this post posts.

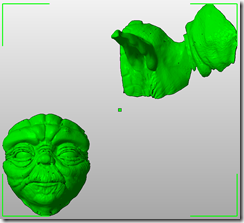

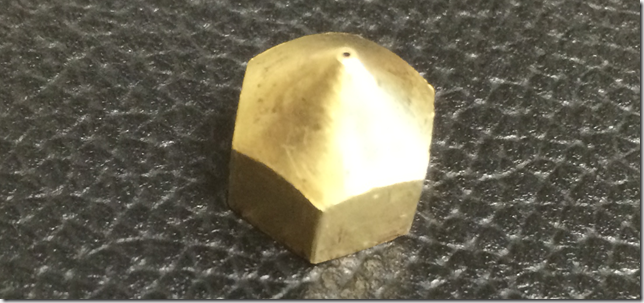

(Those things in the picture, btw, are thingamabobs (technical term) that Jason needs in his Arcade machine build)

Yay! so now that its back to working again, what now? Hmmm..

For future time historians, the list of all posts on the clog: http://geekygulati.com/tag/3d-printing+clog/